Drilling & Well Control Simulation

The ARI Drilling Simulator offers a powerful array of simulation training capabilities to those involved in the oil and gas drilling industry.

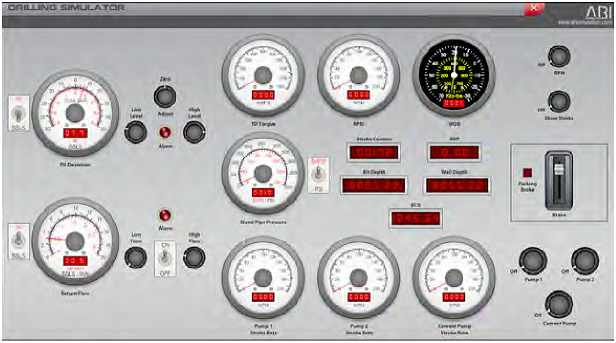

Using the latest technologies in high-fidelity graphics and engineering simulation, the Drilling Simulator provides a complete and detailed immersive simulation experience of the start-to- finish drilling operations on a virtual rig including pipe-handling, tripping in, tripping out, drilling, mud system operation, cementing operations and wellcontrol training.

Combined with the ARI Downhole Simulator, the drilling simulator provides a complete experience from surface tools operations to complex well control scenarios providing a compelling well- control and contingency training environment. Downhole geological parameters can be modified‘on-the-fly’, enabling instructors to introduce extremely challenging training scenarios.

The ARI Drilling and Well Control Simulator is available in a range of modular configurations, from small scale, portable solutions suitable for remote and on-rig training, to containerized portable solutions to full mission multi trainee solutions suitable for deployment in training centers and academic institutions.

The Virtual Drill floor

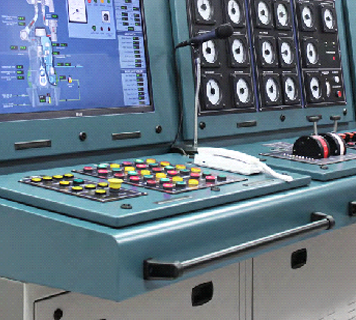

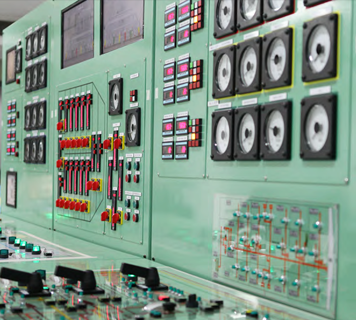

Suitable for use in procedural, operations and well control training, the ARI Drilling and Well Control Simulator provides a completely immersive environment based around the driller and assistant driller workstations in the drillers cabin on the drill floor. With control and monitoring systems that replicate those found on a real rig, including the display and SCADA systems and with virtual CCTV monitoring, training and assessments are conducted in an entirely realistic environment.

Well Control Training Applications

The ARI Drilling and Well Control Simulator includes ARI’s Standard Edition Downhole Model which models pressure, temperature and other conditions in the well into the surface feedback and monitoring systems. Most well control training scenarios can be created using this configuration. For more sophisticated well control applications, ARI offers the Advanced Downhole Module, which supports rheology models, pressure calculations, drill cutting transportation and filter cake formations.

Downhole data can be returned to the surface using LWD or MWD techniques.Complete well profiles can be defined to provide multi-dimensional training features. Special consideration has been given to the modeling of drill string dynamics with full support for effects like drill string whirling, vibration, twist, torsional stick slip, bit bouncing and more.

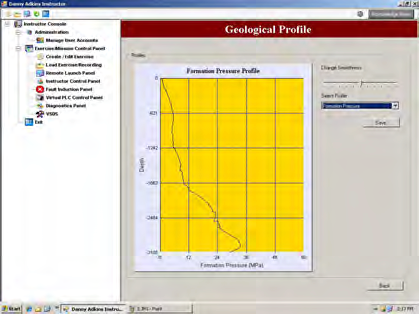

VirtualWellPlan is a module which allows complete well plans to be entered into the system and stored as VirtualWell scenarios. A complete range of geological, pressure and temperature information can be entered and stored into the well plan library in the simulator mission control application. VirtualWellPlan has an easy to use graphical interface and supports vertical, directional and multi-lateral wells and sections.

Other Product

-

OFFSHORE SIMULATORARI Simulation

-

BRIDGE SIMULATORARI Simulation

-

ENGINE SIMULATORARI Simulation

-

DRILLING & Well SIMULATORARI Simulation

-

SUBSEA / ROV SIMULATORARI Simulation

-

MINING SIMULATORARI Simulation

-

Cargo Handling SimulatorARI Simulation

-

Crane SIMULATORARI Simulation

-

Naval SimulatorARI Simulation